The innovation process—Gravity casting method

Gravity casting itself very high purity of raw materials, manufacturing process of injection mold of aluminum solution in Earth's gravity, and naturally cooling, because the molecular casting internal maintenance arrangement structure, fast heat conduction, and uniform. Pot with only a little fire cooked, the pot inside to maintain a certain temperature, so do the dishes taste delicious. And the temperature uniformity is not easy to be burnt pot.

-

South Korea drilling technology process

DNC 5 layer of nano diamond non stick layer, super hardness and super wear resistance, non stick performance excellence.

-

Innovation grease separation technology

Unique pattern surface heat storage energy, cooked to form a micro air cushion, the food surface not freeloaders, reduce oil, low fat intake more healthy, non stick effect is more outstanding, non-stick cookware longer service life.

-

Blend of natural ceramic

Non stick coating natural ceramic technology, through 15000 times the wear test, an ordinary pot can only reach 5500, ceramic coating temperature of 900 degrees, no decomposition, inorganic non-toxic.

-

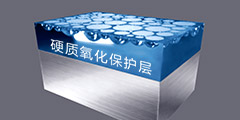

Space hard oxidation

Using space hard oxygen surface treatment technology, super hardness and super wear resistance than steel harder 3 times, excellent rust resistance, super thick wear resistant surface layer is more compact, abrasion resistant performance of super, really no stainless coating.

Cast iron don't rust

99% high purified iron, rich in the human body needs a variety of trace elements, have the assurance of nutrition and health!